ABOUT

PT. Bevananda Mustika has experience of manufacturing Bevananda brand Chainlink netting. While the basic feature of chainlink remains unchanged, the new technology of better galvanization and PVC coating has now increased service life. In the manufacture of Beva Chainlink netting only high quality wire material used. As such, all wire materials used in Beva Chainlink netting have a thick well-adhered zinc coating to provide good corrosion resistance. For more corrosive environments, the wires are coated with thick layer of UV stabilized PVC coating. Our latest technology also provides ad wire material made from Zinc + Alum, it is called Bezinal wire. It provides 6x better protection than standard galvanized wire. Beva Chainlink netting has been used extensively all over Indonesia and has gained wide acceptance by government authorities and engineering consultants and also have SNI certification (SNI 07-6503-2001) from Indonesia Government. wiremesh galvanis , jual kawat harmonika

ADVANTAGES

- Low cost

- Long term performance / durability

- Transparent

- Simple installation

- Retains shape & elasticity

APPLICATIONS

- Highway road barrier

- Railway

- Airport

- Mining construction

- Office building

- Factory

- Cage

- School

- Sport court

- Property / boundary line

COMPLETE SELVAGE PROCESS

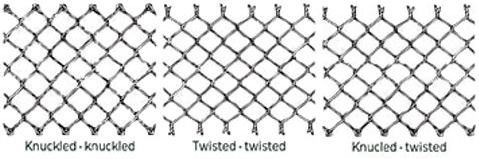

The twisting (barbing) and/or knuckling operations occur simultaneously with the weaving. This means that you lose no time in performing these operations separately. The two salvaging units on either side of the fabric can process fences of three type :

- Knuckled – knuckled

- Twisted – twisted

- Knuckled – twisted

Changing over from knuckling to twisting or vice-versa requires only changing the cam and attachments shown in the picture,

CORRECT MEASURE OF MESH

To give the correct measurement of mesh overture size, netting must be fully stretched. The mesh size is taken as the distance between two parallel wires of the diamond-shaped mesh. It does not include thickness of the wire.

FENCE MATERIAL

The contractor shall construct the chainlink fencing in accordance with the details show in the drawings or as directed by engineers. The complete set of chainlink fencing must consist of line posts ( corner post, intermediate post and standard post), chainlink with proper diameter and standard port), chainlink with proper diameter and mesh, accessories and some lines of barbed wire, if required. The wire size and mesh of chainlink fence hall be adjusted to conform the tolerance specified in BS 1052:19080 and 4102:1963 and SNI 07-6503-2001. For Chainlink with PVC coating, the core wire shall be mild steel with well-adhered galvanized coating. The PVC coating shall be good quality UV stabilized coating, tightly wrapped around the core wire. Customers can choose the attractive color according to their requirements, i.e. green, blue, yellow, white, or else.

PRODUCT SPECIFICATION

TOLERANCES

Beva Chainlink Netting is manufactured according to the tolerances specified in SNI 07-6503-2001 as shown:

STANDARD WIRE STEEL SIZE FOR CHAINLINK WIRE NETTING

| Standard Heavy Galvanized | PVC Coated | Fusion Bonded Quality | ||||

|---|---|---|---|---|---|---|

| Wire Diameter | Tolerance | Core Wire Diameter | Minimum Wire Size | Core Galvanized Wire / Strand | Polimer Coated Wire |

|

| Diameter | Tolerance | |||||

| 1,60 2,00 2,20 2,70 3,00 3,50 3,75 4,00 5,00 | +/- 0,05 +/- 0,06 +/- 0,08 +/- 0,08 +/- 0,08 +/- 0,10 +/- 0,10 +/- 0,10 +/- 0,10 | 1,60 2,00 2,20 2,70 3,00 3,50 3,75 4,00 5,00 | +/- 0,05 +/- 0,06 +/- 0,08 +/- 0,08 +/- 0,08 +/- 0,10 +/- 0,10 +/- 0,10 +/- 0,10 | 2,15 2,70 3,15 3,65 4,00 4,75 5,10 5,40 6,70 | 2,10 2,30 2,50 3,00 3,15 3,65 3,70 4,50 | 2,60 2,80 3,00 3,50 3,65 4,15 4,20 5,00 |

STANDARD MESH SIZE AND TOLERANCE

| Standard Mesh Size | Tolerance |

|---|---|

| 20 ; 30 ; 40 ; 50 ; 55 ; 75; 100 | +/- 3 |

PRODUCT INSTALLATION

The high-quality wire consists of a standard galvanized core wire bonded with a highly adhesive PVC coating. This particular coating technique is preceded by the application and curing of a primer followed by the application of a PVC coating.

This technology combines the typical adhesive properties of fusion bonded coatings with the surface quality of extruded wires resulting in a clean, aesthetic and crack resistant coating. thanks to these features, the PVC coated wire is ideal to be used in environments that are exposed to extreme temperatures, highly corrosive atmospheres and abrasive elements (coastal areas, deserts, etc)

APPLICATIONS

- Fencen coastal areas, deserts, etc

- Slope protection

- Agricultural wire

AVAILABLE COLOR

BENEFITS

- Superior corrosion resistance – less creeping rust that penetrates at cracked points

- Excellent cathodic protection of cut ends

- Less risk of cracking

- Smooth aesthetic coating surface

SPECIFICATION

| Diameter mm | |||

|---|---|---|---|

| Core Galvanized Wire / Strand | Polimer Coated Wire | Polimer Type | Density (g/cm2) |

| 2,10 2,30 2,50 3,00 3,15 3,65 3,70 4,50 | 2,60 2,80 3,00 3,50 3,65 4,15 4,20 5,00 | PVC PVC PVC PVC PVC PVC PVC PVC | 1,35 1,35 1,35 1,35 1,35 1,35 1,35 1,35 |

FINISHES

There are three types of finishing :

Standard Galvanize

With galvanized thickness of 40 – 70 g/m2 (min. zinc coating : Class 1)

Heavy Galvanized

With galvanized thickness of min. 260 g/m2 (conforming BS 443 :1969)

Standard / Heavy Galvanized Wire

Bezinal Wire

Galvanized Wire + PVC Coating

(min. PVC thickness :0.45 mm)

Standard or Heavy Galvanized Wire With PVC Coating

Fusion Bonded (PVC Fused to Wire)